TDR-30

Tri-Deck Roller Finishing Mower

CUTTING WIDTH

29' 6"

CUT HEIGHT RANGE

1/2" to 3 1/2"

RECOMMENDED PTO H.P.

85 to 130

OVERVIEW

Progressive once again has raised the bar in the favor of natural grass producers, offering unmatched productivity on every pass. The TDR-30 Roller Mower was designed with a ‘right sized’ 29’6” cutting swath. Progressive has balanced the need for increased cutting capacity with the available horsepower of tractors commonly used in natural grass production. The TDR-30’s unique Flex-Deck design covers more width per pass and is “easy on the turf” when turning at the headlands, for more acres cut in less time! Focusing on the needs of the natural grass producer, Progressive offers four blade options for the TDR-30. The producer can optimize his cut and maintenance costs depending upon the growing conditions by selecting between two fixed blade lifts and two Pro-EZ Change Blade options - all featuring the renown Progressive cut quality. Like all of our mowers, we designed the TDR-30 as if we were maintaining the mower ourselves, so eliminating all daily service requirements was an important design goal. Maintenance free blade spindles, extended 100 hour PTO shaft greasing intervals and fewer grease fittings all mean more time cutting – less time maintaining. And to keep the TDR-30 cutting over the long term, pivot bushings are easily replaced.

AVAILABLE ONLY IN GALVANIZED DECK SHELL FINISH

BENEFITS

- Lowering the Cost of Operation:

Utilizing a single hydraulic float circuit, the TDR-30 is able to flex and easily track the changing contours often found on natural grass farms.

READ MORE - Familiar Tri-Deck Design:

The TDR-30 takes the easy maneuverability and simple operation of a tri-deck mower – one step further.

READ MORE - Features for the real world:

The TDR-30 creates a new bench mark in value in a wide area natural grass mower – big enough to offer a clear productivity advantage, while containing purchase and operating costs.

READ MORE - Right Sized for Transport:

Designed to permit transport between fields, the TDR-30’s unique Flex Deck allows the wings to be folded a transport height of 13’ and transport width of 9’.

READ MORE - Bolt-on Deck Galvanized decks:

For producers who grow in sandy, or acidic soil conditions, the bolt on deck design allows for inexpensive replacement of the deck if necessary.

READ MORE

SPECIFICATIONS

| Part Number: | 607930G (North America) 607930GC (Worldwide) |

| Recommended PTO H.P.: | 85 to 130 |

| Mowing Capacity: * (Assumes no overlap or turning) | 4 mph 14.3 acres per hour * 6 mph 21.5 acres per hour * 7.5 mph 26.8 acres per hour * |

| Cut Height Range: | 1/2" to 3 1/2" |

| Cutting Width: | 29' 6" |

| Transport Width: | 9' |

| Transport Tires: | 33x16 LL-16.1 10pr |

| Transport Height: | 13' |

| Weight: | 7700 lbs |

| Transport Length: | 17' |

| Std. Equipment: | Some Assembly Required

|

| Opt. Equipment: |

|

Right Sized – 29′ 6″ Wide Cut!

Right Sized – 29′ 6″ Wide Cut! Unique Flex Deck Design:

Unique Flex Deck Design: Pro Lift-N-Turn™

Pro Lift-N-Turn™ Blade Choices

Blade Choices Height of Cut Adjustment (HOC)

Height of Cut Adjustment (HOC)

Simple Tractor Connection

Simple Tractor Connection

Extended PTO Greasing Intervals

Extended PTO Greasing Intervals Right Sized for Transport

Right Sized for Transport Extra-Wide Profile Tire – Standard Feature

Extra-Wide Profile Tire – Standard Feature Bolt-on and Galvanized Deck Shells

Bolt-on and Galvanized Deck Shells Deck Covers

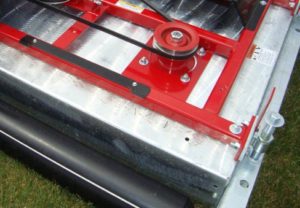

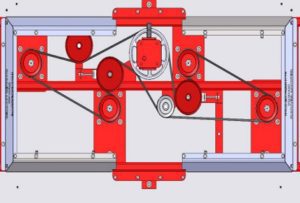

Deck Covers Drive Belt Design and Adjustment

Drive Belt Design and Adjustment