TDR-22

Tri-Deck Roller Finishing Mower

CUTTING WIDTH

22'

CUT HEIGHT RANGE

1/2" to 4"

RECOMMENDED PTO H.P.

65 to 75

OVERVIEW

Proudly built in North America, the TDR-22 is the best value in a Roller Finishing Mower for large-size fields and natural grass production. Unparalleled performance is due to the many standard features that have been field proven over many years of productive use. Full width 6” diameter steel rollers front and back follow the ground contours and help prevent scalping while they smooth the field surface and aid in moisture retention. A high blade tip speed (18,300 fpm) ensures a high quality finish cut, while a choice of four blade types allows the TDR-22 / TDR-22G to be tailored to meet your specific requirements... just to name a few. Together, these changes make the TDR-22 more productive, easier to operate, maintain, and ultimately a better value for natural grass producers worldwide.

AVAILABLE IN PAINTED OR GALVANIZED DECK SHELL FINISH

BENEFITS

- Pro Lift-N-Turn™:

Pro Lift-N-Turn is a popular standard feature on the TDR-22, the mechanical stops of the Pro Lift-N-Turn system protect the mower while the operator protects the headlands.

READ MORE - Ideal Front to Back Deck Balance:

The deck pull points are positioned slightly ahead, but much closer to the deck than how competitive models are designed. This makes the TDR-22 better suited for soft ground conditions.

READ MORE - Ease of Maintenance:

Simplifying service and reducing maintenance requirements were key design objectives to minimize ownership costs, and the TDR-22 delivers!

READ MORE - Bolt-on Deck and Galvanized Option:

For producers who grow in sandy, or acidic soil conditions, the bolt on deck design allows for inexpensive replacement of the deck if necessary.

READ MORE - The second generation TDR-22 changes:

What’s old is new – applies to the TDR-22 especially when it comes to features that give high reliability and low cost of ownership.

READ MORE

SPECIFICATIONS

| Part Number: | 526822 (Painted Decks) 526822G (Galvanized Decks) for North America / 526822C (Painted Decks) 526822GC (Galvanized Decks) for Worldwide |

| Recommended PTO H.P.: | 65 to 75 |

| Mowing Capacity: * (Assumes no overlap or turning) | 4 mph 10.7 acres per hour * 6 mph 16.0 acres per hour * 7.5 mph 20 acres per hour * |

| Cut Height Range: | 1/2" to 4" |

| Cutting Width: | 22' |

| Transport Width: | 97" |

| Transport Tires: | LT305/70R-16 Automotive high floatation |

| Transport Height: | 10' 2" |

| Weight: | 5820 lbs |

| Transport Length: | 15' |

| Std. Equipment: | The tractor is required to have a single hydraulic float circuit.

|

| Opt. Equipment: |

|

Pro Lift-N-Turn™ – Now Easier To Use

Pro Lift-N-Turn™ – Now Easier To Use Improved Front to Back Deck Balance

Improved Front to Back Deck Balance Wide Profile Transport Tire – Optional Feature

Wide Profile Transport Tire – Optional Feature Single Hydraulic Line Connection

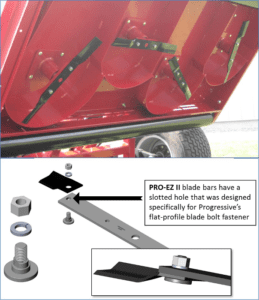

Single Hydraulic Line Connection Blade Choices

Blade Choices Deck Covers

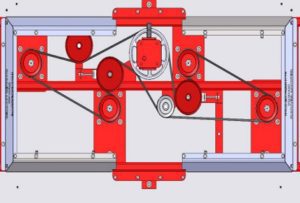

Deck Covers Drive Belt Design and Adjustment

Drive Belt Design and Adjustment Maintenance Free Blade Spindles

Maintenance Free Blade Spindles 100 hour Greasing Interval

100 hour Greasing Interval d Galvanized Deck Shells

d Galvanized Deck Shells Gear Boxes

Gear Boxes Independent Suspension

Independent Suspension Open Frame Design and Construction

Open Frame Design and Construction Height Adjustment

Height Adjustment