Slope-Pro

Remote Controlled Steep Slope Mower

CUTTING WIDTH

52"

CUT HEIGHT RANGE

2.25" TO 8"

WEIGHT

2830 lbs

OVERVIEW

Developed for demanding mowing conditions, the SLOPE-PRO® is a game changing step forward in operator safety and productivity. It features an ultra-low center of gravity for good stability and maneuverability while allowing the mower to cut on side slopes as steep as 50°.

The SLOPE-PRO® slope mower is designed to mow difficult and hazardous locations while minimizing the risks to an operator, the equipment, or the terrain.

The SLOPE-PRO® is designed, manufactured and distributed world-wide by Progressive Turf Equipment Inc.

BENEFITS

- Built for hazardous areas:

The SLOPE-PRO® is suitable for hazardous and difficult terrain, including:

READ MORE

• Roads and highway

• Parklands and estates

• Landfill Sites

• Railway embankments

• Power line right-of-ways

• Riparian zones (reservoir and canal embankments)

• Military bases / restricted environments - Tracks, not wheels:

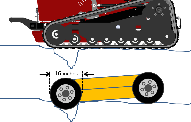

Mowing hillsides with crevices caused by localized water erosion issues is a particular concern for wheel based slope mowers. Depending upon the width and depth of the crevice, a wheel based slope mower may not be able to cross and complete the job at hand.

READ MORE - Spikes / Winches not required:

Many competitive mowers can achieve similar angles as the Slope-Pro, but require additional help to do it. The Slope-Pro achieves all operating angles without the need for turf damaging spikes, or tethers and winches that require constant adjustment by the operator.

READ MORE - Simple and productive; gets the job done:

The Slope-Pro® mower deck contains two counter rotating blades and provides a productive 52″ wide cut per pass. Maintenance free blade spindles reduces operating cost and provides ownership peace of mind.

READ MORE - The Slope-Pro Design Advantage:

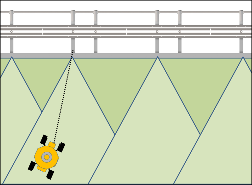

The SLOPE-PRO has several key design advantages that is important in a remote controlled mower. The cutting deck is positioned between the tracks, not ahead of the mower like other models. The mid-mount position of the cutting deck will more closely follow changing ground contours as it rides with the position of the tracks. Two 9” wide and 48” long tracks provide excellent traction and stability while reducing ground pressure to under 4.5psi.

READ MORE

SPECIFICATIONS

| Part Number: | 604101 |

| Cut Height Range: | 2 1/4" TO 8" |

| Engine: | 747cc Kohler Command-Pro EFI, selected for economy, performance, and reliability |

| Speed: | Infinitely variable from 0 to 4.3 mph - with Work and Travel ranges |

| Traction Drive: | Hydrostatic - independent pumps & wheel motors with integrated fail-safe brakes |

| Cutting Deck Drive: | Belts and electromagnetic clutch (remotely operated from controller with interlock) |

| Cutting System: | 2 Blade Rotary with grass / mulching blades. Maintenance free blade spindles |

| Slope Capability: | 50° side slope, 35° fore and aft, without spikes or external support devices |

| Tracks: | Turf friendly - 9" wide x 48" long footprint for low ground contract pressure |

| Remote Control: | Remote control of all mower functions, 300' max operating radius recommended |

| Fuel Tank: | Two 3.2 gallon removable tanks with level site gauges and quick disconnect lines |

| Cutting Width: | 52" |

| Transport Width: | 78" |

| Transport Height: | 38 3/4" TO 44 1/2" |

| Weight: | 2830 lbs |

| Transport Length: | 80" |

| Std. Equipment: |

|

| Opt. Equipment: | Factory Installed

|

Ability to go over the Toughest Terrain

Ability to go over the Toughest Terrain Built Productive

Built Productive Built for the operator in mind

Built for the operator in mind