Pro-Max 36

36' Finishing Mower System

CUTTING WIDTH

36' (when mated with a TD92)

CUT HEIGHT RANGE

3/4" to 5"

RECOMMENDED PTO H.P.

80 to 100

OVERVIEW

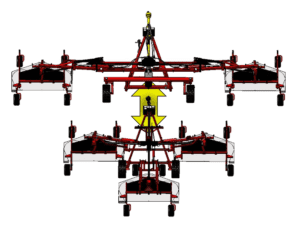

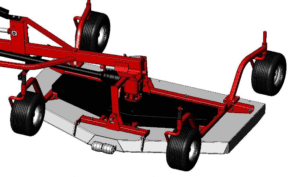

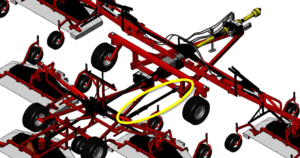

The PM-36 when paired with the Progressive TD92 rotary finishing mower, creates the Pro-Max 36 mowing system. Towed by a ~100 H.P. tractor, the Pro-Max 36 mowing system delivers a 36 foot wide cut swath and can mow up to 33 acres per hour. The Pro-Max 36, although a large machine has a light footprint making it ideal in wet conditions. The PM-36 and the TD92 share many of the same components which helps keeps long term ownership costs low.

AVAILABLE IN PAINTED OR GALVANIZED DECK SHELL FINISH

BENEFITS

- Pro-Max Mowing System:

The Progressive Pro-Max Mowing System is a 5 deck finishing mower that is the combination of the highly successful Progressive TD92 and the PM-36. Together they provide a wide 36 foot cut swath and give a whole new meaning to productivity!

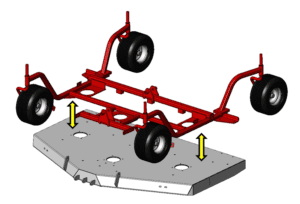

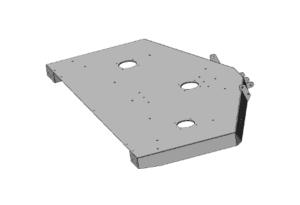

READ MORE - Bolt-on Deck Shell:

For producers who grow in sandy, or acidic soil conditions, the bolt-on design allows for inexpensive replacement of the deck shell if necessary.

Painted or Galvanized Deck Shell Versions Available

READ MORE - Ease of Maintenance:

Simplifying service and reducing routine maintenance requirements has been a key objective of Progressive’s for the past several years. Ensuring that many service parts remain backwards compatible to older models is also a key consideration.

READ MORE - What Hasn't Changed?:

While there are many new features on the PM-36, there is a lot that has stayed the same as the TD92. A tried and true design, the complete Pro-Max 36 mowing system uses componentry that have a proven field history, for peace of mind over the long term.

READ MORE - Different Blade Options:

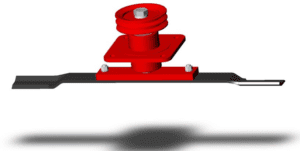

Focusing on the needs of the natural grass producer, Progressive offers four blade options for the Pro-Max 36.

READ MORE

SPECIFICATIONS

| Part Number: | 629236 (Painted) 629236G (Galvanized) for North America / 629236C (Painted) 629236GC (Galvanized) for Worldwide |

| Recommended PTO H.P.: | 80 to 100 (when mated with a TD92) |

| Mowing Capacity: * (Assumes no overlap or turning) | 2 mph 8.8 acres per hour * 4 mph 17.5 acres per hour * 6 mph 26.0 acres per hour * 7.5 mph 32.8 acres per hour * |

| Cut Height Range: | 3/4" to 5" in 3/8" steps |

| Cutting Width: | 36' (when mated with a TD92) |

| Turning Radius: | Zero |

| Transport Width: | 13' (when mated with a TD92) |

| Transport Tires: | P275 / 60R 15 Automotive Radials |

| Transport Height: | 13' (when mated with a TD92) |

| Weight: | 8700 lbs |

| Transport Length: | 29' 8" (when mated with a TD92) |

| Std. Equipment: |

|

| Opt. Equipment: | A Pro-Max Mowing System requires two double acting hydraulic circuits, one with float capability

|

Pro-Max Mowing System

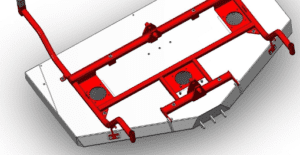

Pro-Max Mowing System Bolt-on Deck Shells

Bolt-on Deck Shells Your choice: Galvanized or Painted Deck Shells

Your choice: Galvanized or Painted Deck Shells Heavier Spindle Mounting

Heavier Spindle Mounting Heavier Construction = Longer Life

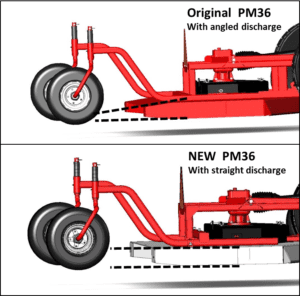

Heavier Construction = Longer Life Improved Clipping Discharge

Improved Clipping Discharge Now Deck Cleaning Is Easier Than Ever

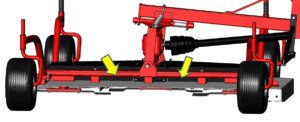

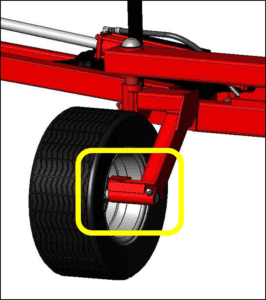

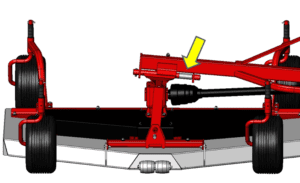

Now Deck Cleaning Is Easier Than Ever Bolt-on Transport Axle

Bolt-on Transport Axle Maintenance Free Blade Spindles

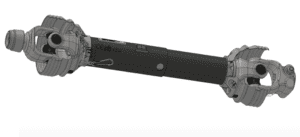

Maintenance Free Blade Spindles 100 hour PTO Greasing Interval

100 hour PTO Greasing Interval Progressive GROWS with your business

Progressive GROWS with your business Gear Boxes

Gear Boxes Cut Height – Easy to Adjust

Cut Height – Easy to Adjust Drawbar Connection

Drawbar Connection Excellent Floatation

Excellent Floatation Adjustable Overlap

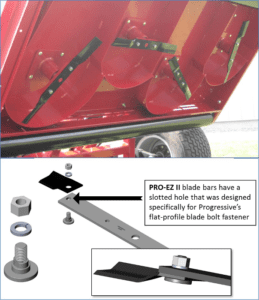

Adjustable Overlap Pro-Teck Edge™ Fixed Blades

Pro-Teck Edge™ Fixed Blades PRO-EZ II™ Replaceable Tip Blades

PRO-EZ II™ Replaceable Tip Blades