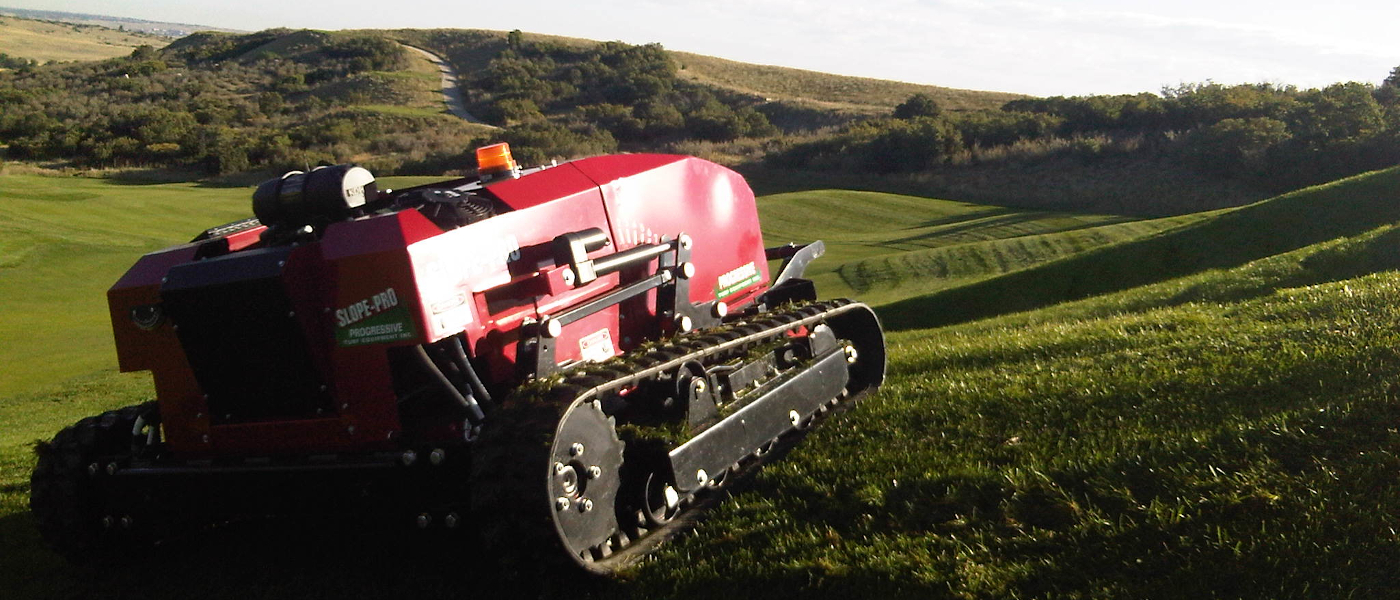

TDR Roller Mowers

Reliable production units for the Natural Grass Industry

Find out More about our Roller MowersWelcome to Progressive Turf Equipment

Thank you for your interest in Progressive Turf Equipment and our offering of pull-behind, rotary finishing mowers.

For over 30 years, Progressive has been designing and manufacturing innovative, rotary finishing mowers for natural grass producers, golf courses and municipal / general use around the globe. Our investment in the latest 3D CAD software, integrated ERP system and CNC manufacturing work-cells, drives our customer commitment to provide high quality products that deliver unmatched Productivity, Reliability, Durability and Quality of Cut. We enjoy strong brand recognition and a solid reputation within the industry for well designed, durable products that provide lasting value to the user. Our longevity is a testament of our commitment our products and our customer’s needs.

Why Choose Progressive Turf Equipment?

What Our Customers Say

One machine has helped our bottom line …. now that’s value! Todd Doig, Equipment Superintendent, Seaforth Golf Club, Seaforth Ontario Canada

We’ve run our Pro-Flex mower for four seasons now and being able to cut roughs, mow around trees, and then blow leaves in the fall all with one machine has helped our bottom line.”

One machine that makes me look good! Rod Betteridge, Canadian Baseball Hall of Fame, St. Mary's, Ontario Canada

The quality of the playing fields is of utmost importance, but so is the appearance of the hills that surround our complex. The Pro-Flex Roller cuts both beautifully.

Cut as low as a half inch! Tim Mills, Facility Manager, Calgary Polo Club

We bought our 15′ Progressive roller mower in July 2011 and we are very pleased with this mower.

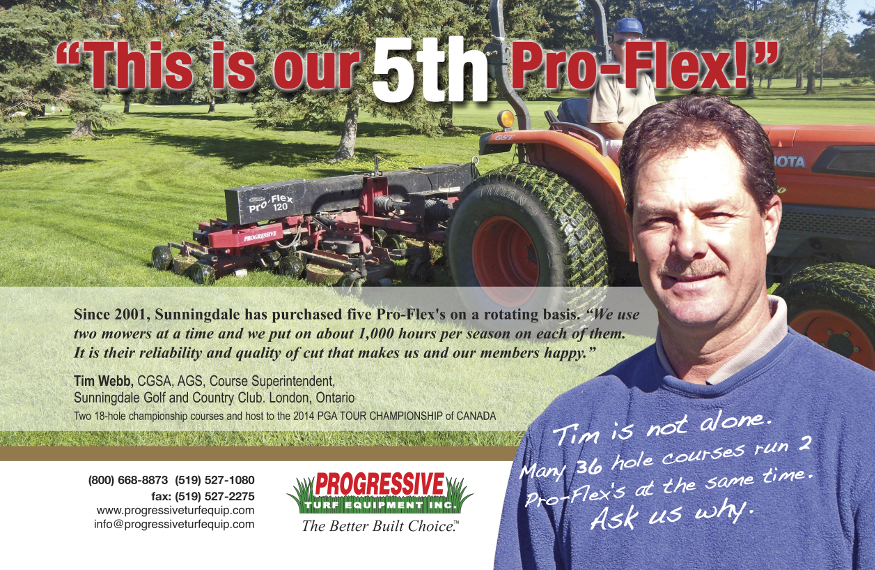

This is our 5th Pro-Flex! Tim Webb, CGSA, AGS, Course Superintendent, Sunningdale G.C.C., London, Ontario

Since 2001, Sunningdale has purchased five Pro-Flex’s on a rotating basis. We use two mowers at a time and we put on about 1000 hours per season on each of them. It’s their reliability and quality of cut that makes us and our members…

It’s even better this time around! David MacKay, Equipment Manager, Ainsdale GC, Kincardine, Ontario

We got our first Pro-Flex in 2000 and we just retired that for a new 2015 model. Given our heavy use, I like the reliability of this mower and the new reduced maintenance design makes my job easier.

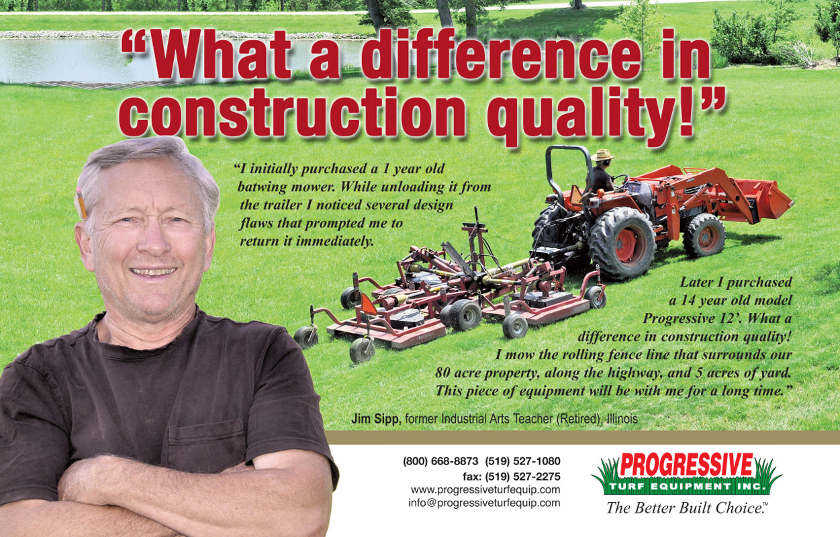

What a difference in construction quality! Jim Sipp, former Industrial Arts Teacher (retired), Illinois

I initially purchased a 1 year old batwing mower. While unloading it from the trailer I noticed several design flaws that prompted me to return it immediately. Later I purchased a 14 year old Progressive 12′ mower. What a difference in construction quality!